Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes XLPE (Cross-liked Polyethylene)

XLPE (Cross-liked Polyethylene) Silaine Crosslinking Advantages

Silaine Crosslinking Advantages صفحه Silaine Crosslinking Advantages

|

Silaine Crosslinking Advantages

|

|

|

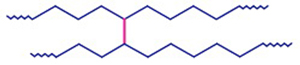

C-to-C bond: rigid

Structure of PE crosslinked by Peroxide or Radiation |

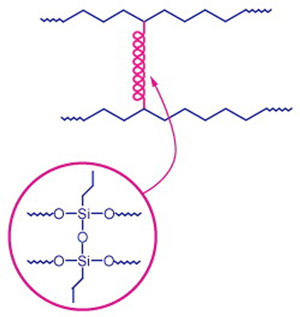

Si-O-Si bond: flexible

Structure of PE crosslinked by Silaine Technology |

|

2) Better Tensile and Impact Performance In general, Crosslinking of a polymer reduce slightly its impact performance. Silaine crosslinked polyolefins are linked through a Si-O-Si moiety instead of the C-to-C bond created via peroxide or radiation cure. Siloxane bridges are less rigid than C-to-C bonds and give flexibility to the crosslinked polymer . |

|

|

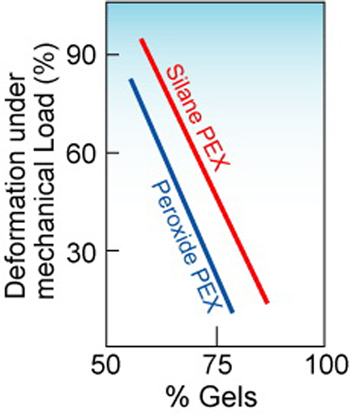

3) Reduced Creep In Materials Science, creep is the tendency of a solid material to slowly move or deform permanently under the influence of stresses. It occurs as a result of long term exposure to high levels of stress that are below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods, and near melting point. Creep always increases with temperature. The rate of this deformation is a function of the material properties, exposure time, exposure temperature and the applied structural load. It is well known that Creep Resistance increases with the crosslinking density of a polymer. This can be easily explained by the fact that in a crosslinking system polymer chains are linked together and can’t slide against each other. PE crosslinking increases its Creep Resistance Figure 1 below shows how the croslinking density (%gel) influences the deformation under mechanical load of crosslinked PE. |

|

|

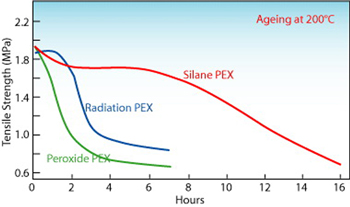

4) Better Weatherability Studies have demonstrated that the use of Silaine crosslinking provide material with better heat ageing. This figure compares the mechanical properties retention of PEX crosslinked using different technologies at 200°C . It shows clearly that Silaine PEX exhibits better retention in tensile strength than irradiation and peroxide PEX . |

|